Location: Home >Passivated magnesium

Passivated magnesium

Passivated magnesium powder is mainly used in the desulfurization production of iron and steel. The

- 1:Small angle of repose, good mobility

- 2:In desulfurization, the dosage is small, the treatment time is short, and the reaction speed is fast

- 3:The molten iron is cooled to the bottom, the amount of slag is small, and the desulfurization effect is good.

-

Packaging can be customized according to customer needs

-

Email: cathy@hncczz.com

■ detail intruduction

Passivated magnesium powder is mainly used in the desulfurization production of iron and steel. The product "spherical" magnesium powder has a small angle of repose, good fluidity, small dosage in desulfurization, short treatment time, fast reaction speed, and molten iron cooling bottom. The amount of slag is small, and the desulfurization effect is good.

Features of spherical passivated magnesium powder:

Dark gray spherical passivated magnesium powder: less dosage and shorter processing time. Passivated spherical magnesium powder has been widely used in developed countries as a desulfurizer for iron and steel smelting. Iron and steel enterprises must produce qualified special steel. Dark gray spherical passivated magnesium powder Specifications: 2-0.21mm (10-65 mesh), 0.85-0.18mm (20-80 mesh), 0.99-0.21mm (16-65 mesh), 0.85-0.21mm (20-65 mesh) mesh), 0.85-0.30mm (20-50 mesh), to meet customer requirements. Physical and chemical properties and technical standards. Passivated magnesium powder is gray-white, and the particle shape is round or unequal round. The ignition point of the passivated magnesium powder is between 560 and 600 °C. The flame retardant time of the passivated magnesium powder at 1000°C is not less than 15 seconds. Passivation magnesium powder should not contain impurities and agglomeration, but there can be a small amount of passivation layer powder. Magnesium powder inspection procedures. Look at the appearance of the color, shape, etc. of the passivated magnesium powder with your eyes. Particle size, bulk density, mg, cao, caf content. 2. , magnesium oxide, phosphorus, sulfur and hydrogen. OCheck according to set standards. Check the burning point and flame retardant time according to special equipment and methods. The samples are batched (2 tons/batch). usage and effects.

The main purpose of spherical passivation magnesium powder:

In the production of high-quality steel, passivated spherical metal magnesium powder is used for removal and deoxidation, so that the SuFe element in the steel is less than 0.004%. Using Fe-Si-Mg master alloy instead of Fe-Si-Mg master alloy as nodularizing agent for ductile iron is irreplaceable compared with other paint stripping methods in producing high-quality steel. Restoring and accelerating pressure drilling and wells into late-stage velocity for the oil industry. In the chemical industry, the military industry is an effective dehydrating agent and oxidant, and it is also a magnesium alloy powder metallurgy material.

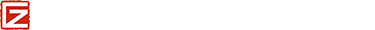

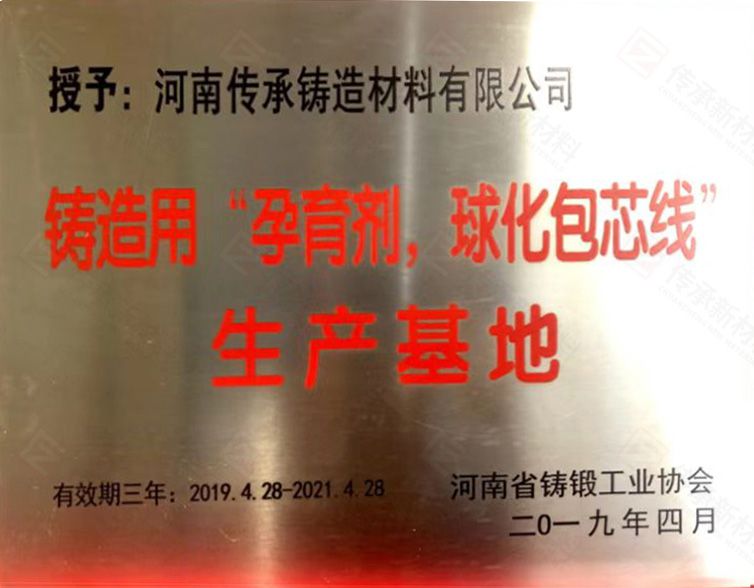

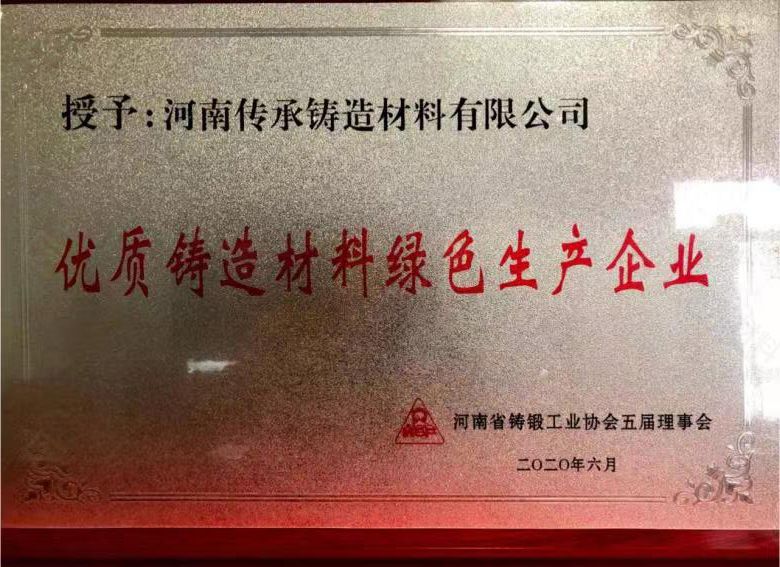

■ Enterprise overview

■ Recommended Products

■ Message/Inquiry

Remarks: Confirm the sample index, model weight and delivery address