Spheroidizing agent series rare earth magnesium ferrosilicon alloy

1: Characteristics of ductile iron and ductile ironNodular cast iron has the characteristics of stee

- 1:New melting process to reduce Mg oxidation (MgO)

- 2:Composition is stable

- 3:New pouring process reduces slag involvement

- 4:New casting mould with significantly reduced MgO, slag and gas content

-

Packaging can be customized according to customer needs

-

Email: cathy@hncczz.com

■ detail intruduction

1: Characteristics of ductile iron and ductile iron

Nodular cast iron has the characteristics of steel and cast iron, with high strength and toughness, and the characteristics of cast iron damping damping at present, the global output of nodular cast iron in about 20 million tons of Our country is mainly rare earth magnesium nodular cast iron production process.

2: Composition and production control of ductile iron

1.Basic chemical elements in ductile iron

Carbon (C): low temperature nodular cast iron exists in the form of graphite, solid solution C and cementite. Properly increasing the content of C can reduce the brittle transition temperature and improve the high content of C in the toughness of cast iron, which is easy to cause graphite floating, especially in large section nodular cast iron.

Silicon (Si): promote graphitization of elements, promote the formation of ferrite low temperature nodular cast iron, to strictly control the Si content.

Mn:Promote the formation of cementite For large section nodular cast iron, to strictly control the content of Mn.

P: Deterioration of cast iron properties and severe reduction of toughness, especially low temperature toughness.

S: Sulfur controls the growth morphology of graphite. Nodular cast iron can be produced only when S content is very low.

3: Spheroidizing agent

The metallurgical chemical reaction between spheroidizer and S eliminates the influence of S on the growth morphology of graphite, and the main components of inhibiting interfering elements are Mg and Re, which have the following categories :(1) pure Mg; (2) blocks made of pure Mg and iron filings; (3) rare earth ferrosilicon magnesium alloy (the most extensive spheroidizing agent, can produce a variety of ductile iron); (4) yttrium heavy rare earth iron silicon spheroidizing agent (production of large section ductile iron); (5) Barium containing rare earth ferrosilicon magnesium alloy (ferrite nodular cast iron with high production requirements); (6) Other spheroidizing agents (copper magnesium alloy, nickel magnesium alloy, magnesium ferrosilicon alloy, etc.)

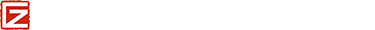

The composition and use of the company's main spheroidizing agent are shown in Table 1. The new melting process reduces the oxidation of Mg (MgO) and the composition is stable. New casting process to reduce slag involvement; New casting molds significantly reduce MgO, slag and gas content.

Table 1 Composition and application of main spheroidizing agents

Type | Code name | Chemical component wt% | Explanation | ||||||||

Re | Mg | Si | Mn | Ca | Ti | Al | Ba | Fe | |||

Spheroidizing agent | FeSiMg5Re1 | 1~2 | 5~6 | £43 | - | 1.5~2.5 | <0.5 | <0.5 | Bal. | Low magnesium 4%-5.5%Mg spheroidizing agent, | |

FeSiMg6Re2 | 2~3 | 6~7 | £43 | - | 2~3 | <0.5 | <0.5 | Medium magnesium 6%-7%mg spheroidizing agent, | |||

FeSiMg8Re3 | 2~4 | 7~9 | £44 | - | 2~3.5 | £1.0 | <0.5 | ||||

FeSiMg6Re4 | 3~5 | 5~7 | £44 | - | 2~3.5 | £1.0 | |||||

FeSiMg8Re5 | 4.0~<6.0 | 7.0~9.0 | £44.0 | £4.0 | £4.0 | £2.0 | - | ||||

FeSiMg8Re7 | 6.0~<8.0 | 7.0~<9.0 | |||||||||

FeSiMg10Re7 | 6.0~<8.0 | 9.0~11.0 | High magnesium spheroidizing agent, | ||||||||

FeSiMg8Re9 | 8.0~<10.0 | 7.0~<9.0 | |||||||||

FeSiMg10Re9 | 8.0~<10.0 | 9.0~11.0 | |||||||||

FeSiMg8Re11 | 10.0~<13.0 | 7.0~10.0 | |||||||||

FeSiMg13Re14 | 13.0~15.0 | 12.0~15.0 | £44.0 | £5.0 | |||||||

FeSiMg8Re16 | 15.0~<17.0 | 7.0~10.0 | |||||||||

FeSiMg8Re18 | 17.0~<20.0 | 7.0~10.0 | |||||||||

FeSiMg10Re21 | 20.0~<23.0 | 9.0~11.0 | |||||||||

4:Series spheroidizing agent

1. All kinds of yttrium base heavy rare earth heavy rare earth spheroidizing agent, spheroidizing agent is suitable for large section castings, delay spheroidizing recession to prevent massive graphite.

2. (low) aluminum spheroidizing agent for castings prone to subcutaneous porosity defects and castings requiring aluminum content in liquid iron.

3. After spheroidizing with pure Ce and La spheroidizing agent, the molten iron was purified and the graphite sphere was rounded.

4. Low silicon spheroidizer is suitable for casting plants that use a large amount of returnable charge.

5. Nickel magnesium spheroidizing agent is used in high nickel austenitic ductile iron.

5: Also according to the requirements of users, the company can assist in the debugging of components, to meet the requirements of raw material castings structure process of application manufacturers.

Product specifications can be customized according to customer requirements

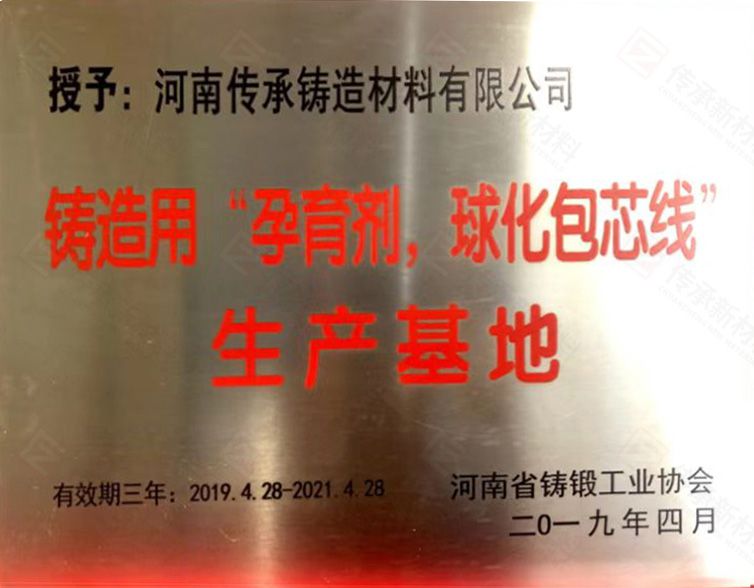

■ Enterprise overview

■ Recommended Products

■ Message/Inquiry

Remarks: Confirm the sample index, model weight and delivery address