Location: Home >Ferromanganese

Ferromanganese

In steelmaking, it is used as a deoxidizer and alloy additive, and it is an iron alloy with a large

- 1:In steelmaking, used as deoxidizer and alloy additive

- 2:It is a ferroalloy with a large amount

-

Packaging can be customized according to customer needs

-

Email: cathy@hncczz.com

■ detail intruduction

In steelmaking, it is used as a deoxidizer and alloy additive, and it is an iron alloy with a large amount. The manganese ore used for smelting ferromanganese generally requires 30~40% manganese, the ratio of manganese to ferromanganese is greater than 7, and the ratio of phosphorus to manganese is less than 0.003. Before smelting, manganese carbonate ore needs to be roasted, and powder ore needs to be sintered and agglomerated. Generally, ore with high iron and phosphorus content can only be used in combination, or through selective reduction to obtain manganese-rich slag with low iron and low phosphorus. Coke is used as a reducing agent during smelting, and some factories also use lean coal or anthracite. The auxiliary raw material is mainly lime, and silica is generally added when smelting manganese-silicon alloys.

The general international standard of carbon ferromanganese is 75-80% manganese. In order to adapt to the raw material conditions of low-grade manganese ore, China has stipulated the grades with lower manganese content (electric furnace ferromanganese contains more than 65% manganese, and blast furnace ferromanganese contains 50% manganese. %above). In the past, blast furnaces were mainly used for smelting carbon ferromanganese. With the development of the electric power industry, the use of electric furnaces has gradually increased. Western Europe and China mainly use blast furnaces, Norway and Japan all use electric furnaces, and new ferromanganese plants in the Soviet Union, Australia, Brazil and other countries also use electric furnaces.

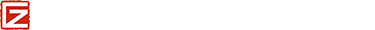

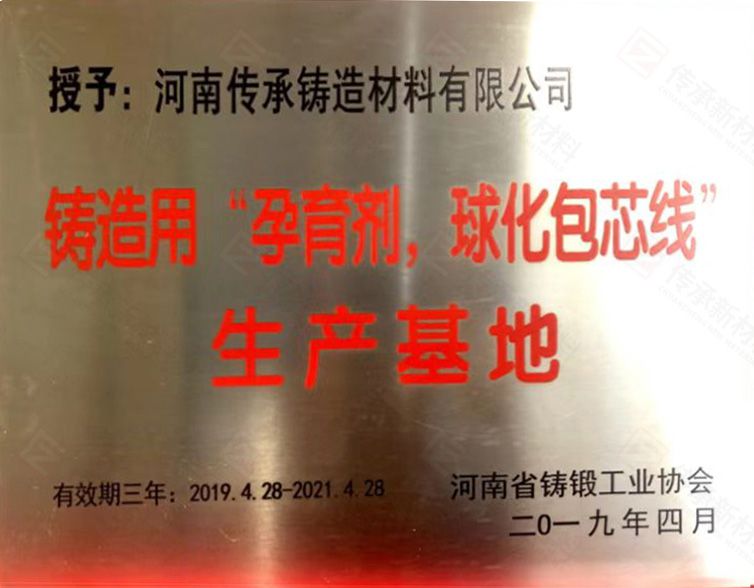

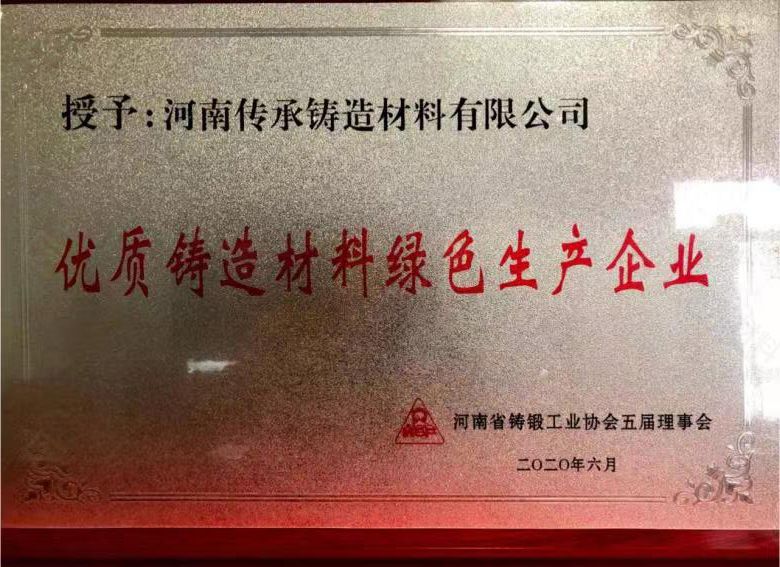

■ Enterprise overview

■ Recommended Products

■ Message/Inquiry

Remarks: Confirm the sample index, model weight and delivery address